Miller Dynasty 300 Multiprocess Tig Welder Wireless Foot Control Complete Wire Feeder Package

$19,017.00

The Miller Dynasty 300 Multiprocess Wireless Complete is an advanced 300 amp welding system that comes complete with ArcReach Suitecase 12 wire feeder, Coolmate™ 1.3 water cooler, Small Runner cart and TIG torch package. The 300 Multiprocess is the only welder you’ll need on the jobsite to perform MIG, Stick, AC/DC TIG welding and air carbon arc gouging.

Description

[vc_row][vc_column][vc_tta_tour][vc_tta_section title=”What´s Included” tab_id=”1605708525500-5ede2d35-fd3f”][vc_column_text]

Miller Dynasty 300 Multiprocess Wireless Foot Control Complete with ArcReach Suitcase 12 Wire Feeder 951940

The Miller Dynasty 300 Multiprocess Wireless Complete is an advanced 300 amp welding system that comes complete with ArcReach Suitecase 12 wire feeder, Coolmate™ 1.3 water cooler, Small Runner cart and TIG torch package. The 300 Multiprocess is the only welder you’ll need on the jobsite to perform MIG, Stick, AC/DC TIG welding and air carbon arc gouging.

The Miller Dynasty 300 Multiprocess has built in TIG pulse and advanced AC/DC wave forms and provides up to 300 amps of welding output. Adjustable TIG pulse can be set from 0.1 to 500 pulses per second (pps). AC TIG frequency adjustment has a range from 20-400 Hz. Extremely low amperage TIG output allows you to go down to as low as 2 amps on AC and 1 amp on DC. Wave forms are adjustable in both AC and DC pulsed TIG welding modes for a truly customized welding arc.

The Miller Dynasty 300 Multiprocess can weld materials up to 3/8 inch thick. It can go just about anywhere and run on just about any input power, single-phase or three-phase. Auto-Line™ senses input voltage and phase and instantly adjusts the welder to the optimal operational settings without manual linking. The simplified user interface with large 4.5 inch LCD display helps ensure proper weld parameters for your job. The Pro-Set™ mode eliminates the guesswork from set up by automatically choosing the most common weld settings for your application.

When using a water-cooled TIG torch, the 300 Multiprocess utilizes Cooler-On-Demand™ technology to save energy and prolong the life of your optional TIG torch and Miller Coolmate™ 1.3 cooler. It also comes standard with CPS (Coolant Power Supply), an integrated 120V dedicated outlet for running your Coolmate water circulator.

IP23 rating — This equipment is designed for outdoor use. It may be stored, but is not intended to be used outside during precipitation unless sheltered.

![]()

Processes

- AC/DC TIG (GTAW)

- Pulsed TIG (GTAW-P)

- Stick (SMAW)

- Air carbon arc (CAC-A)

- MIG (GMAW)ApplicationsShipbuilding

Construction

Precision fabrication

Heavy fabrication

Pipe and tube fabrication

Rental

Maintenance and repair

Features

- Built-in CV circuitryFor MIG welding when paired with an OPTIONAL Miller voltage sensing feeder.

- Easy-to-understand interface with 4.5-inch LCD displayEnsures proper machine setup and parameter selection

Informative on-screen explanations and dynamic images enhance the parameter selection process

- Full AC featuresIncluding advanced waveforms and wide ranges of balance and frequency.

- Built-in pulserReduces heat input; adds arc stability.

- USB Front panel portProvides the ability to easily update software, back-up settings and transfer saved weld programs from one unit to the next.

- Program memoryAllows easy naming, saving and recalling of favorite weld settings.

Deliver more productivity by eliminating the need to manually set the parameters

Deliver consistent quality by welders of all skills

- Locks and limitsProvides control of weld parameter ranges minimizing deviation from the welding procedure specification (WPS).

- Pro-Set™ feature (professional settings)Eliminates the guesswork when setting weld parameters. Use Pro-Set when you want the speed, convenience and confidence of pre-set controls. Simply select the feature and adjust until Pro-Set appears on the display. The Pro-Set feature is available for Balance, Frequency, Pulse, and DIG parameters.

- Auto-Line™Provides state-of-the-art flexibility by automatically connecting to 208-575 VAC, single- or three- phase power without removing the covers to relink the power source. No longer is there a concern if you have the correct machine for the shop or the job site.

- Cooler Power Supply (CPS).Integrated 120-volt dedicated-use receptacle to power the Coolmate™ 1.3. The power switch on the Dynasty also activates the receptacle to help prevent torch failure.

- Lift-Arc™ TIGArc starting provides x-ray clean welds without the use of high frequency.

- Blue Lightning™ TIGHigh-frequency arc starter for non-contact arc initiation. Provides more consistent arc starts and greater reliability compared to traditional HF arc starters. Easy to set and increases productivity.

- Cooler-On-Demand™Operates the auxiliary cooling system only when needed, reducing noise, energy use, and airborne contaminants pulled through the cooler.

- Wireless remote compatibleFully compatible with Miller wireless remote control solutions

- IP23 rating –This equipment is designed for outdoor use. It may be stored, but is not intended to be used outside during precipitation unless sheltered.AC TIG Features

- AC Pulsed TIG (0.1 to 500 pps)Controls the amount of heat going into the weld to minimize warping or distortion, especially on thin material.

- AC Balance (30-99%)Controls the amount of oxide cleaning (amperage time in EN) which is essential for high quality welds on aluminum.

- AC frequency (20-400 hz)Controls the width of the arc cone and the force of the arc.

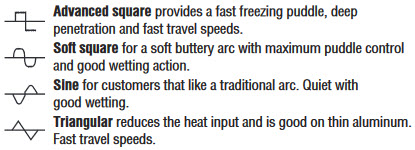

- Advanced AC Waveforms

DC TIG Features

DC TIG Features - DC Pulsed TIG (0.1 to 500 pps)Controls the amount of heat going into the weld to minimize warping or distortion, especially on thin material

- Exceptionally smooth and precise arcFor welding exotic materials.

- Pulse WaveformsSquare provides a fast freezing puddle for ultimate arc control.

Sine produces a reduced audible sound and provides a more fluid puddle that is good for overlaying applications.

Triangular provides a quick-forming puddle while further reducing heat for thin materials.MIG Features

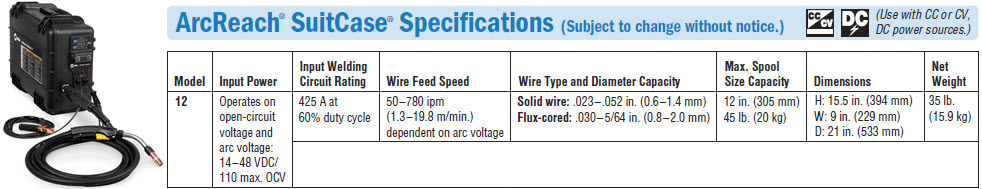

- CV outputGives this unit MIG process capabilities with ArcReach® Suitcase® 12 voltage sensing feeder.

The feeder is powered off of the arc voltage of the power source and can run both solid and flux-cored wiresStick Features (AC/DC)

- Tailored arc control (DIG)Allows the arc characteristic to be changed for specific applications and electrodes.

Smooth running 7018 or stiffer, more penetrating 6010.

- Hot Start™Adaptive control provides positive arc starts without sticking.

- AC frequency controlAdds stability for smoother welds when AC Stick welding.

- Stick-StuckDetects if the electrode is stuck to the part and turns the welding output off to safely and easily remove the electrode.

Comes complete with

- Miller Dynasty 300 Multiprocess Welder with CPS (Cooler Power Supply)

- Adjustable shoulder strap

- 8 ft (2.4 m) primary cord

- ArcReach Suitcase® 12 voltage sensing wire feeder

- 15 foot, 300 amp MIG gun

- 8 ft. 1/0 wire feeder connection cable with Tweco connectors

- Wireless remote foot control

- Water-cooled TIG torch package with 25 ft. leads and accessories

[/vc_column_text][/vc_tta_section][vc_tta_section title=”Specifications” tab_id=”1604679959828-9ce4c8f3-67ce8b9a-5535″][vc_column_text]

Specifications

PRODUCT LITERATURE

PROCESSES

GENERAL SPECIFICATIONS

| Title | Dynasty® 300 Multiprocess Wireless Foot Control Complete |

|---|---|

| Industries Interests | Construction Education / Training Infrastructure Maintenance and Repair – Field Operations Maintenance and Repair – In Plant Mechanical Contracting Shipbuilding Work / Service Trucks |

| Material Thickness | Aluminum 0.012 in. (0.3 mm) – 3/8 in. (9.5 mm) Steel 0.004 in. (0.1 mm) – 3/8 in. (9.5 mm) |

| Weldable Metals | Aluminum Specialty Metals Stainless Steel Steel |

| Input Voltage | 208 V 220/230/240 V 380/400 V 460/480 V 575/600 V |

| Rated Carbon Diameter | 3/16 in (4.8 mm) |

| Input Phase | 1- and 3-Phase |

| Input Hz | 50/60 Hz |

| Current Type | AC / DC |

| Max Open Circuit Voltage | 60 VDC |

| Amperage Min | 1 A |

| Amperage Max | 300 A |

| Welding Mode | CC/CV |

| Weld Output | 250 A at 20 V, 60% duty cycle |

| Net Width | 8.6 in |

| Net Height | 13.6 in |

| Net Length | 22.5 in |

| Net Weight | 310 lbs |

[/vc_column_text][/vc_tta_section][/vc_tta_tour][/vc_column][/vc_row]